The traditional linear model of production and consumption in the chemical manufacturing industry is no longer viable in the face of mounting environmental concerns. Embracing the circular economy offers a more sustainable approach that focuses on reducing waste, reusing materials, and recycling resources.

In this blog post, we will delve into the concept of the circular economy and explore its potential to transform the chemical manufacturing sector.

Rethinking Product Design: Cradle-to-Cradle Principles

One of the key pillars of the circular economy is designing products with a cradle-to-cradle approach. This means considering the entire lifecycle of a product, from sourcing materials to disposal, to minimize waste and maximize recyclability.

Chemical manufacturers can adopt innovative design strategies that prioritize the use of renewable resources, non-toxic materials, and modular product components, facilitating easier recycling and reducing environmental impact.

Implementing Closed-Loop Systems: Waste Reduction and Resource Recovery

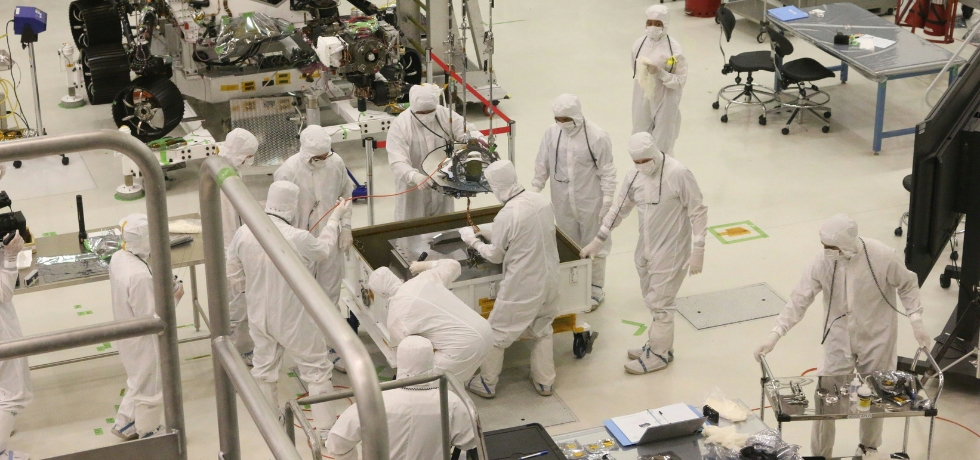

Closed-loop systems play a crucial role in the circular economy by minimizing waste generation and promoting resource recovery. Chemical manufacturers can implement strategies such as industrial symbiosis, where waste from one process becomes a valuable input for another, fostering collaboration and creating synergies among companies.

Additionally, technologies like solvent recovery, advanced filtration, and wastewater treatment can enable the recycling and reuse of valuable resources, reducing the need for virgin materials.

Embracing Renewable Energy: Powering Sustainable Operations

Transitioning towards renewable energy sources is a fundamental step for chemical manufacturers aiming to embrace the circular economy. Investing in solar, wind, or hydroelectric power not only reduces greenhouse gas emissions but also provides a reliable and sustainable energy supply.

Renewable energy integration can power manufacturing processes, contribute to carbon neutrality goals, and reduce dependence on fossil fuels, further enhancing the sustainability of the chemical manufacturing sector.

Collaboration and Industry Partnerships: Accelerating Change

The shift towards a circular economy requires collaboration and partnerships among stakeholders across the chemical manufacturing industry. Companies can work together to develop innovative solutions, share best practices, and create closed-loop supply chains.

Collaboration with research institutions, government bodies, and non-profit organizations can also drive the development of sustainable technologies, policies, and regulations that support the circular economy transition.